Human-Machine Interface (HMI) software represents the bridge between operators and industrial systems, enabling seamless communication and control in manufacturing environments. As automation continues to reshape industries worldwide, understanding HMI software & programming becomes essential for engineers, technicians, and manufacturing professionals seeking to optimize their operations.

This comprehensive guide explores the fundamentals of HMI software & programming, covering everything from basic concepts to advanced implementation strategies. Whether you’re designing your first interface or upgrading existing systems, you’ll discover practical insights to enhance your industrial automation projects.

What is HMI Software & Programming?

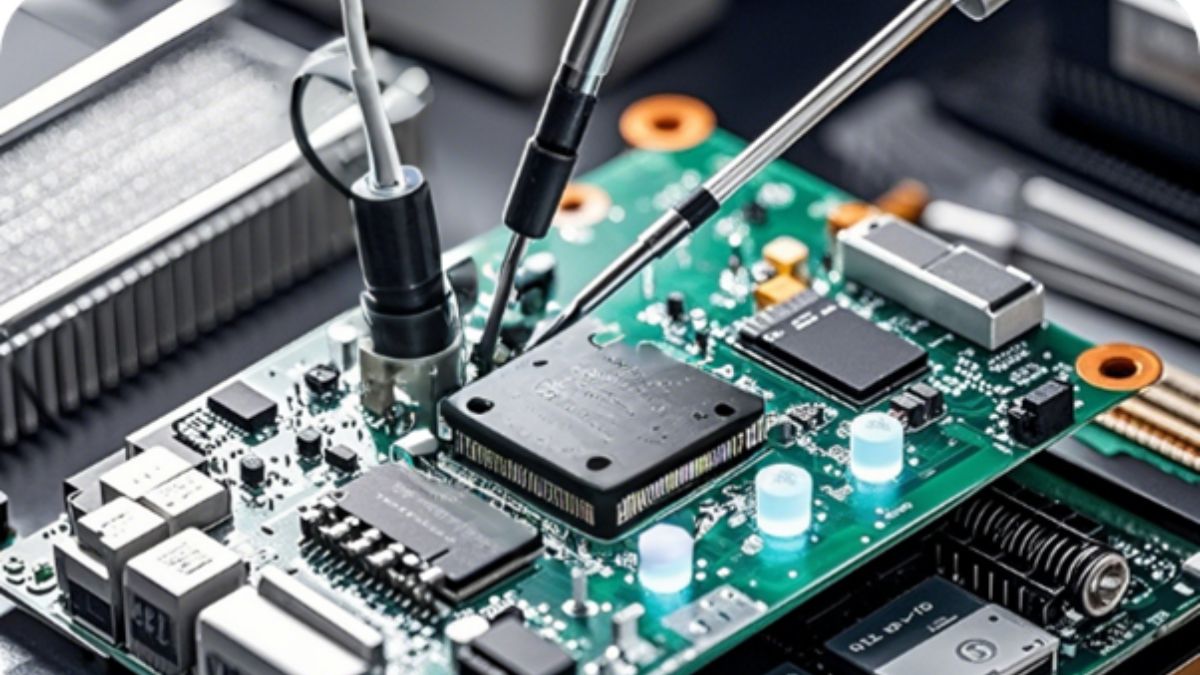

HMI software & programming encompasses the tools and techniques used to create intuitive interfaces between human operators and automated systems. These software solutions enable operators to monitor processes, input commands, and receive critical system feedback through graphical displays and interactive controls.

Modern HMI software platforms provide drag-and-drop functionality, extensive graphics libraries, and powerful scripting capabilities. Programming these interfaces involves configuring screens, setting up data connections, creating alarms, and implementing security protocols to ensure reliable operation.

The programming aspect focuses on establishing communication protocols between the HMI and various devices such as PLCs, drives, and sensors. This creates a unified control environment where operators can manage complex industrial processes from centralized workstations.

Key Features of Modern HMI Software

Intuitive Design Tools

Contemporary HMI software & programming platforms offer sophisticated design environments that streamline interface development. These tools include pre-built templates, customizable widgets, and vector graphics support that enable rapid prototyping and deployment.

Advanced color palettes and animation capabilities help create visually appealing interfaces that enhance operator understanding. Multi-language support ensures global accessibility, while responsive design features adapt interfaces to different screen sizes and orientations.

Real-Time Data Integration

Effective HMI software & programming requires seamless data exchange between field devices and operator interfaces. Modern platforms support numerous industrial protocols including Modbus, Ethernet/IP, and PROFINET, ensuring compatibility with diverse equipment manufacturers.

Real-time trending capabilities allow operators to monitor process variables over time, identifying patterns and potential issues before they impact production. Historical data logging provides valuable insights for process optimization and regulatory compliance.

Alarm Management Systems

Comprehensive alarm management represents a critical component of HMI software & programming. Advanced platforms provide hierarchical alarm structures, priority-based notifications, and acknowledgment tracking to ensure operators respond appropriately to system events.

Smart alarm filtering prevents information overload by grouping related alarms and suppressing redundant notifications. Customizable alarm displays help operators quickly identify and address the most critical issues affecting production.

Programming Approaches and Best Practices

Structured Development Methodology

Successful HMI software & programming projects follow systematic development approaches that ensure consistent results. Begin by analyzing operator requirements and workflow patterns to design interfaces that support natural working methods.

Create standardized graphics libraries and naming conventions that promote consistency across multiple screens and projects. Modular programming techniques enable code reuse and simplify maintenance activities throughout the system lifecycle.

Security Implementation

Modern HMI software & programming must incorporate robust security measures to protect industrial systems from unauthorized access. Multi-level user authentication ensures operators access only the functions appropriate to their roles and responsibilities.

Encrypted communication channels protect data integrity during transmission between HMI stations and field devices. Regular security updates and password policies maintain protection against evolving cybersecurity threats.

Performance Optimization

Efficient HMI software & programming requires careful attention to system performance and responsiveness. Optimize screen refresh rates to balance real-time updates with system resource consumption.

Implement intelligent data polling strategies that prioritize critical process variables while reducing network traffic. Memory management techniques prevent system slowdowns during extended operation periods.

Industry Applications and Use Cases

Manufacturing Operations

HMI software & programming plays a vital role in modern manufacturing facilities, providing operators with centralized control over production lines, quality systems, and material handling equipment. Interactive dashboards display key performance indicators, enabling quick identification of bottlenecks and efficiency opportunities.

Integration with enterprise systems allows real-time production reporting and inventory management. Batch processing capabilities support recipe-based manufacturing while maintaining traceability requirements.

Water Treatment Facilities

Water treatment operations rely heavily on HMI software & programming for monitoring treatment processes, managing chemical dosing systems, and ensuring regulatory compliance. Automated reporting features generate required documentation while reducing administrative workload.

Geographic information system integration provides visual representation of distribution networks, helping operators identify maintenance needs and optimize system performance.

Energy Management

Power generation and distribution facilities utilize HMI software & programming for grid monitoring, load balancing, and emergency response coordination. Advanced visualization tools display complex electrical networks in intuitive formats that support rapid decision-making.

Predictive maintenance algorithms integrated within HMI platforms help identify equipment issues before failures occur, reducing downtime and maintenance costs.

Implementation Strategies for Success

Project Planning and Requirements Analysis

Effective HMI software & programming projects begin with comprehensive planning phases that clearly define operator needs and system objectives. Collaborate with end users to understand their daily workflows and identify opportunities for improvement.

Document functional requirements thoroughly, including screen layouts, data sources, and alarm conditions. This foundation supports efficient development and reduces costly modifications during later project phases.

Testing and Validation Procedures

Rigorous testing protocols ensure HMI software & programming implementations meet performance and reliability standards. Simulate various operating scenarios to verify proper system responses under normal and abnormal conditions.

User acceptance testing involves operators in validation processes, confirming that interfaces support their work effectively. Load testing verifies system performance under maximum expected conditions.

Training and Documentation

Comprehensive training programs ensure operators can utilize HMI software & programming features effectively. Develop role-based training materials that focus on functions relevant to specific job responsibilities.

Maintain detailed system documentation including operating procedures, troubleshooting guides, and maintenance schedules. Regular training updates keep operators current with system enhancements and best practices.

Future Trends and Technologies

Cloud Integration and Remote Access

Modern HMI software & programming increasingly incorporates cloud-based capabilities that enable remote monitoring and control of industrial systems. Secure web-based interfaces allow authorized personnel to access critical information from any location.

Edge computing technologies bring advanced processing capabilities closer to industrial equipment, reducing latency and improving system responsiveness. Hybrid architectures combine local control with cloud-based analytics and reporting.

Artificial Intelligence and Machine Learning

AI-powered features within HMI software & programming platforms provide predictive insights and automated optimization recommendations. Machine learning algorithms analyze historical data to identify patterns and suggest process improvements.

Intelligent alarm management systems learn from operator responses to reduce false alarms and improve notification relevance. Natural language processing enables voice-activated controls and simplified operator interactions.

Maximizing Your HMI Investment

HMI software & programming represents a critical investment in operational efficiency and competitiveness. Success depends on selecting appropriate platforms, following structured implementation approaches, and maintaining systems through regular updates and training programs.

Consider partnering with experienced integrators who understand both technical requirements and operational challenges. Their expertise can accelerate implementation timelines while ensuring systems meet long-term business objectives.

Focus on scalable solutions that can grow with your organization’s needs. Modern HMI software & programming platforms provide the flexibility to expand functionality and integrate new technologies as requirements evolve.