Professional plumbers need to have adequate knowledge of the safe operation tactics of walk-behind saws. This ensures an effective application of this tool, thereby getting the ultimate work done smoothly. This also helps in preventing injuries.

Walk-behind saws are powerful tools that are used to cut hard surfaces, like asphalt and concrete. While they can be easily operated, one mistake may also result in accidents. So, it is imperative that anyone working with a walk-behind saw must know the right way to use it.

If you are a plumber handling this tool, you must ensure safe usage; otherwise, serious injuries can occur. So, it is imperative that you learn about the essential safety measures when using this tool. This ensures the completion of different cutting tasks without any accidents.

Walk-Behind Saws: Need for Safety

Walk-behind saws are effective in cutting a hard surface, but a single mistake might lead to a huge accident. The blade of this walk-behind concrete cutter can be damaged, or the entire machine might stop functioning.

Maintaining adequate safety features helps a professional from exposure to dust. Therefore, you will be prevented from getting any respiratory disease.

Plumbers often use gas-powered walk-behind saws for cutting. They excrete carbon monoxide, which is hazardous. This indicates the need for effective handling, and an experienced plumber must possess the needed awareness.

Steps to Follow for a Safe Usage of Walk-Behind Saws

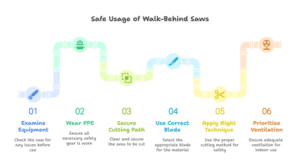

A plumber needs to follow certain steps to ensure the safe usage of a walk-behind saw. This helps to prevent any accident or injury. Let’s explore the steps that a pro plumber must acknowledge while applying walk-behind saws.

Figure: Safe Usage of Walk-Behind Saws

Step 1: Examining the Equipment before Application

Always check the tool before using it in any operation. The saw might contain a 14-inch concrete cutting blade, but that must not be worn. Check that the chords are in working condition. Also, ensure that none of the machinery components are loose.

To combat machine failure, pre-application inspection is highly significant. You can lower injuries up to a certain extent.

Step 2: Always Wear PPE

A plumber can be affected while using a walk-behind saw because it might eject debris into the surroundings. Well, you need not worry about this if you are wearing PPE.

Your protective equipment must comprise hand gloves, a safety helmet, safety boots with saw protection, hearing protection, and others. Never wear loose clothes.

Step 3: Identifying and Securing the Cutting Path

To ensure an effective cut, you need to mark the path by using chalk. This helps to figure out the exact areas where the operation will be done. Remove any water or debris so that you do not slip during the operation. Let’s check out the pre-cut considerations.

Step 4: Using the Correct Blade

Walk-behind saws may have 14-inch concrete cutting blades or blades of any other size. You need to use different blades to cut concrete and asphalt.

A professional plumber possesses adequate knowledge about the different types of blade materials and their applications. Let’s see suitable blade materials for different cutting planes.

Blade Materials |

Cutting Planes |

Diamond blades |

Concrete and bricks |

Carbide-tipped blades |

Light block and fiber cement |

Carbon steel blades |

Non-ferrous metals |

Bi-metal blades |

Wood |

Table: Blade Materials vs Cutting Planes

Step 5: Using the Right Technique

Handling a walk-behind saw with a 14-inch concrete cutting blade must be done with caution. If you are an expert plumber, you should know what is the ideal technique. Let’s check out some tips that can help you choose the perfect technique.

- Always hold the handles with two hands

- Never put any pressure on the machine

- Always prefer a straight-line cutting

- The entire cutting will be done by the blade, so don’t rush.

Step 6: Prioritizing the Right Ventilation Type for Indoor Use

You need to prioritize ventilation if you are operating inside. Gas like carbon monoxide is emitted from the gas-powered models. Cover your nose and mouth when using the saw with PPE; you may also ask people around to leave the area temporarily. Ensure that there is adequate ventilation for the gas and dust particles to escape.

What Are the Safety Considerations of Applying Walk-Behind Saws?

Wrong application of walk-behind saws may result in accidents and injuries. While using this walk-behind concrete cutter, you have to obey certain regulations, which vary from one country to another.

- In the USA, plumbers need to follow specific OSHA guidelines. The main considerable aspects are cutting, respiratory protection, and others. A professional plumber has to always follow legal compliance.

- In Ireland, the Safe Pass Certification is a prerequisite for operating walk-behind saws. This is mandatory for all individuals who work on construction sites.

Summary

Walk-behind saws call for caution at every step. Plumbers need to follow different safety measures. Prioritizing safety needs ensures a proper application of this tool. Besides selecting the right blade to ensure effective cutting, they need to wear PPE and see to it that no person is standing nearby.

The right kind of application will ensure that the work gets done effectively.

Ensure Safer Application of Walk-Behind Saws

You can use a walk-behind saw for any construction or plumbing work. And for this, you must be aware of the safety measures. Also, remember to purchase the tool from a reliable tool supplier so that your work gets easier.