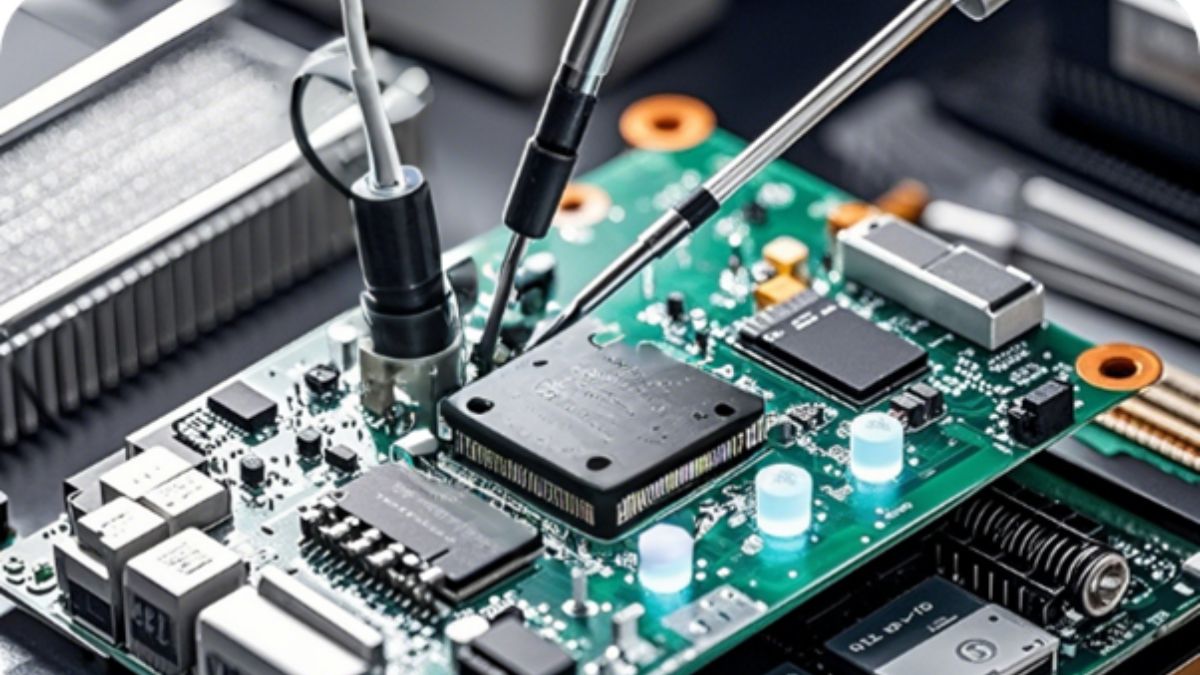

From high output engines, and to the very heart of EV’s themselves, the unmatched precision of CNC Swiss lathes is manufacturing the transportation future.

The automotive industry is transforming more than just its powertrains; it’s shifting the very idea of automotive architecture. As vehicles become more complex and defined through software, the need for physical components that are smaller, stiffer, and more reliable is paramount. This movement is benefiting from a manufacturing process inherently known for its microscopic precision: Swiss machining services. Any manufacturer of auto parts looking to compete in this new era, better know how to perform or partner with Swiss machining companies, and that is no longer a nice to have, but a must have.

The advantages of the Swiss-type lathe, via its guide bushing and zero material deflection capabilities, make it ideally suited for automotive applications. It allows for the manufacturing of long, slender, and complex parts, all while tolerances remain consistent through part runs and we all know how important that is for the auto industry when they are needing high volume runs.

The Technical Benefits: Why Swiss Screw Machining is Best for Automotive

Swiss screw machining for automotive projects benefits three main areas:

Unbeatable Precision and Consistency. Components such as fuel injector nozzles, transmission sensors, and valve lifters need to be dimensionally stable. The part needs consistent absolute precision, (even with high volume production runs) which is why Swiss precision machining is imperative. If you create the same part a million times, it should be identical. End users do not want a mass recall due to a component failure.

Efficient in High Volume. Modern CNC swiss machining centers are able to operate in lights out production. Through robotics and automated bar feeding components, a swiss lathe machining cell can run 24/7 with little or no human interaction. Fine-tuning lots was important to automotive machining while balancing cost per component.

Allowing for complexity in a single set-up. A major advantage of a swiss lathe machine is its multi-axis capabilities since it can allow for the full machining of the part in one operation. Also, live tooling can mill, drill, and tap features on the part without it leaving the collet. This eliminates cumulative error from multiple operation set-ups with the goal to machine precision transmission components.

Electrifying Precision: The Indispensable Need for Precision in EV Manufacturing

Transitioning to electric vehicles has not negated the ever-present need for precision; it has only transformed it. Electric vehicles consist of extremely complicated components that require a level of precision never demanded previously.

- EV Battery Connector Machining: At the heart of any EV is its battery pack. The copper or aluminum connectors contained, in particular, must be manufactured and machined with immaculate surface finishes and exact geometries to ensure the proper level of electrical resistance, no overheating, and maximum energy efficiency. Micro swiss machining is the only manufacturing and machining solutions capable of manufacturing, machining, and scaling these key ev battery connector machining components in needed dependability.

- Power Electronics and Sensors: Constantly managing the electrical power being consumed and produced in an EV powertrain are inverters, converters, and a spectrum of sensors requiring miniature, complex housings and pins, sometimes out of specialty alloys. These tiny yet critical components once again absolutely require the precision found in Swiss CNC machining processes.

- Thermal Management Systems: EV batteries require cooling with precision, and the tiny and complex components used in liquid cooling plates and manifolds are perfect candidates for the swiss screw machining process as leak-proof seals depend on level of precision as well as where fluid flow occurs and where it does not.

Beyond the EV: Preserving the Internal Combustion Engine

While the electric vehicle market grows, the observable mass of the internal combustion engine market is substantial as well and continues to evolve. The need for precision high volume automotive machining persists as innovations grow and opportunities exist.

- Performance and Efficiency: To extract more horsepower with better fuel economy, engine components are generated with the tightest tolerances ever achieved – Turbocharger vanes, high-pressure fuel pump parts, variable valve timing components, excellent candidates for Swiss machining for performance and efficiency.

- Lightweighting: Swiss lathe machining is an excellent solution to evaluating, locating handling high-strength, lightweight materials, aluminum and titanium space-age alloys, with such attention to reducing vehicular weight and emissions.

Choosing The Right Manufacturing Partner: An Engineer’s Checklist

When selecting a swiss machining services provider for a custom automotive parts manufacturer, your choice is a significant technical decision. Your perfect manufacturing partner must simply be more than just a shop, but an essential extension of your engineering team.

- Experience With Industry: Do they have experience with a track record serving the automotive industry in the automotive space and understand the unique demands of the automotive industry, particularly with respect to cnc machining for electric vehicles?

- Quality Certifications: ISO 9001 and IATF 16949. These are fundamental. IATF 16949, the automotive specific certification is indicative of a commitment to meeting the highest quality management and process standards.

- Experience With Materials: The ability to address machining the basic materials found in automotive applications, engine-grade high-strength alloys, conductive copper for electronics, and aluminum in a variety of applications.

- Design for Manufacturability (DFM): A premier manufacturing partner will provide you proactive DFM feedback, adjusting various design proposals to look for potential improvements in performance, reduce cost, and improve manufacturability without compromising the design intent.

Conclusion: Engineering the Road Ahead

The future of all transportation, electrical or hybrid, will be engineered on a technically demanding foundation of precision. No other form of error-free manufacturing offers the precision, accuracy and capabilities of swiss machining services for parts manufacturer to confidently engineer, build, and design the safest, most efficient, and most reliable vehicles the market demands.

By leveraging the ever-growing power of CNC Swiss machining, the entire automotive industry has the opportunity to navigate through the complex path of evolution and advanced technologies with the utmost assurance that every piece and part, no matter how small, is made precisely.

Bio:

[Flamingo Peng] is an advanced manufacturing consultant in automotive and mobility technologies. At Falcon CNC Swiss, we are an auto parts manufacturer and provider of precision Swiss machining services, supplying mission-critical components to leaders in the automotive and electric vehicle industries.