A poorly equipped excavator operator is a danger to everyone. That’s why opting for an excavator training course can help you learn vital aspects of operating excavators and help you boost your skills. Learn more about this by reading our post.

The rise in construction projects in the UK has led to an increase in the demand for excavators.

Apart from construction, some other projects in the UK that have fueled the demand for excavators include renewable energy and mining projects. This demand can be seen in the projected sale of 27,498 excavators in the UK by 2029.

Naturally, the increase in the number of excavators means that the abovementioned industries would be looking for skilled professionals. So, if you have been planning to undergo an excavator training course for this reason, you’re in the right place.

That’s because you will get to learn about what this course will teach you, the certifications you’ll receive, and the other career opportunities. Continue reading for more information!

What Are the Core Skills Taught in Excavator Training Courses?

A proper training course will teach you skills like equipment operation and controls, safety procedures, and compliance. You’ll also learn digging, trenching, and grading techniques, soil types, and management and preventive maintenance.

1. Equipment Operation and Controls

First and foremost, you will learn how to operate the different types of excavators. These are mini, wheeled, dragline, long-reach, skid steer, and crawler excavators, to name a few.

Take a look at the brief table below to understand what each does:

Type of Excavator |

What It Is Used For |

|---|---|

Mini Excavator |

In parking lots and indoor areas for construction and demolition |

Wheeled Excavator |

Excavation and road-based projects |

Dragline Excavator |

Underwater and road excavation |

Long-reach Excavator |

Heavy-duty digging and industrial demolition |

Skid Steer Excavator |

Residential construction projects to remove piled-up debris |

Crawler Excavator |

Landscape grading, mining, and digging trenches |

Table 1: Types of Excavators You Will Learn To Operate With An Excavator Training Course

You will be taught how to operate the various components of these excavators, like the control panels, levers, and hydraulic systems. The course will also teach you how to handle the various attachments like breakers, compactors, and rippers.

The training will combine simulation through AR and VR and real-life on-field training.

2. Digging, Trenching, and Grading Techniques

Digging refers to the action of actually moving the soil or dirt from one place and dropping it on another.

Trenching refers to the process of creating long, narrow tunnel-like incisions in the dirt or trenches. Excavators make trenches to lay utilities like underground water pipes or electric cables.

Grading refers to the leveling of the land to obtain an even slope and ensure a stable ground for construction.

During the excavator training course, you will learn how to dig the ground for optimal grading evenly. You will also learn the relevant calculations for the same.

Apart from that, you will be taught how to inspect the ground thoroughly and to check for previous installations of pipelines via blueprints.

This knowledge will help you go about trenching carefully.

You will also be taught how to understand load-bearing charts. These charts will help you carry the correct amount of dirt to avoid breaking the arms of the digger.

3. Soil Types & Load Management

The kind of soil you operate on will determine how effectively you’re able to dig, trench, and grade. It will also impact your excavator’s performance. That’s why you’ll learn about the different types of soils, like A, B, and C.

While A is the most stable type of soil to excavate, C is the least stable type of soil. Consider the table below for a better understanding.

Type of Soil |

Properties |

Examples |

|---|---|---|

A |

Cohesive soil (where particles stick together) with a compressive strength of 1.5 tons per square foot of area or more |

Clay loam, Sandy clay, Clay |

B |

Cracked or cohesive disturbed soil with an average compressive strength between 0.5 to 1.5 tons per square foot of area or more |

Silt loam, Gravel (angular), Silt |

C |

Granular soil particles that don’t stick together with a low compressive strength of 0.5 tons per square foot of area or less |

Sand, Gravel |

Table 2: Types of Soils Taught To Trainees During An Excavator Training Course

You’ll be taught how to operate the excavator on these types of soil and prevent unnecessary accidents due to the soil breaking.

4. Safety Procedures and Compliance

The excavator training course will also teach you about the various safety procedures you should follow. You will be taught the necessary protocols to operate safely on the field.

For instance, you will be taught how to press the emergency stop button and evacuate the excavator. After that, you will be taught how to calmly assess and study the situation to prevent panicking.

The course will also teach you about the correct machine start-up and shutdown protocols. For instance, you will be taught to check the following before machine start-up:

- Whether the parking brake is engaged

- If any people are around

- Follow the excavator manufacturer’s instructions

You will also learn what to do in case you’re locked out of your excavator. In the case of crusher training, on the other hand, you will learn how to work safely around the crusher equipment. These involve the conveyor belt and rotating equipment.

Finally, the crusher or excavator course will also teach you the various UK-specific regulations. These will include LOLER, PUWER, and those of the HSE.

These regulations govern all aspects of operating lifting and power-operated equipment as well as employee performance and safety protocols.

5. Preventive Maintenance & Equipment Checks

The last part of the course will involve the knowledge of inspecting the tires, tracks, hoses, and fluid levels daily. You will also be taught how to identify the early signs of wear and tear or hydraulic failure.

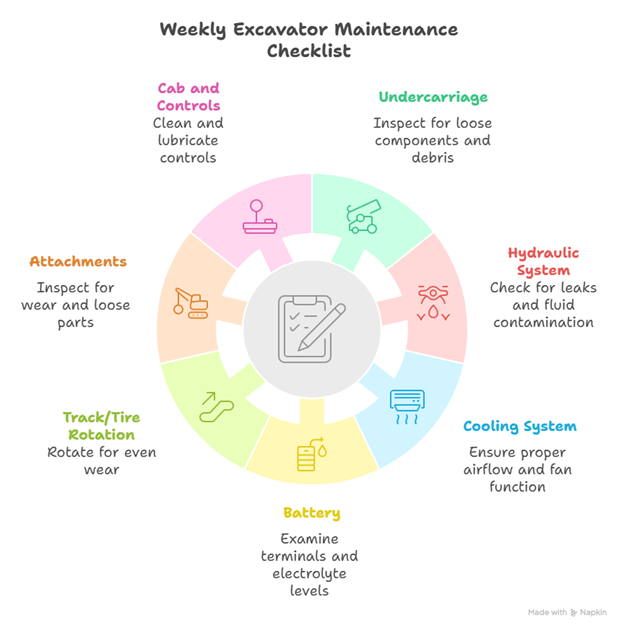

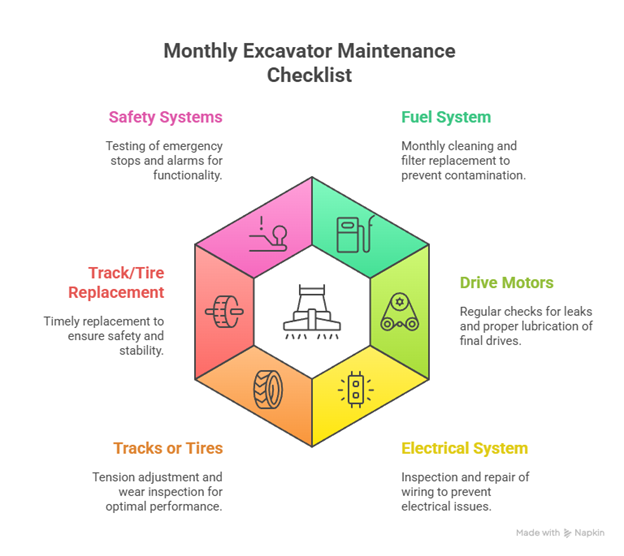

Finally, you will also be taught how to maintain your excavator properly, on a weekly and monthly basis.

Consider the infographics below for a better visual:

What Do You Get After the Excavator Training Course?

Once you successfully pass the excavator training course, you will receive a:

- Certificate of Completion

- Proof of equipment competency, such as CPCS and NPORS cards

The CPCS is more publicly recognised and denotes that you are qualified to handle

construction machinery. On the other hand, NPORS controls the eligibility of excavator operators to handle them.

What Career Opportunities Can You Get After an Excavator Training Course?

You can get various opportunities at construction companies, mining firms, municipalities, and demolition firms after completing your course. Some possible roles you may get are:

- Excavator Operator

- Equipment Maintenance Tech

- Crusher Loader Operator

- Site Safety Lead

The exact role will depend on your preferences and qualifications.

Wrapping Up

Excavator training is a smart career move. You will get to learn many vital skills that will help you operate the equipment safely and professionally. However, if you wish to gain more experience, you can also opt for crane and crusher training.

The additional training will help you become a specialised worker and help you boost your skills and earning potential.