Regulatory compliance in medical device manufacturing is not optional; it is the backbone of safety, efficacy, and trust in any device that goes near or inside a human body. From design through production, validation, and distribution, manufacturers face stringent rules from agencies like the FDA, EMA, and others. In this journey, precision equipment plays a critical role. Whether one is creating micro-surgical tools or implantable components, the tools used must deliver high accuracy, traceability, and consistency. And when manufacturers also work with partners like a polyurethane processing equipment manufacturer to produce specialized components, or use polyurethane casting machines for parts that will contact bodily tissues, the demands for precision rise even more. This blog examines how precision equipment supports regulatory compliance, what standards matter, and how manufacturers can ensure they stay ahead.

Understanding the regulatory landscape

Key standards and bodies

Medical device manufacturers must comply with international and regional standards, such as:

- ISO 13485 for medical device quality management systems.

FDA’s Quality System Regulation (21 CFR Part 820) in the United States. - EU MDR (Medical Device Regulation), IVDR (for diagnostics) in Europe.

- Specific performance and safety standards, such as IEC 60601 for electrical medical equipment and IEC 62366 for usability.

Key regulatory requirements

Several requirements mainly rely on the precision of equipment:

- Design verification and validation

- Process validation, including qualification (IQ, OQ, PQ) of manufacturing equipment.

- Material traceability, biocompatibility, where applicable.

- Strict tolerances, reproducibility, and minimization of defects.

The role of precision equipment in compliance

Why precision matters

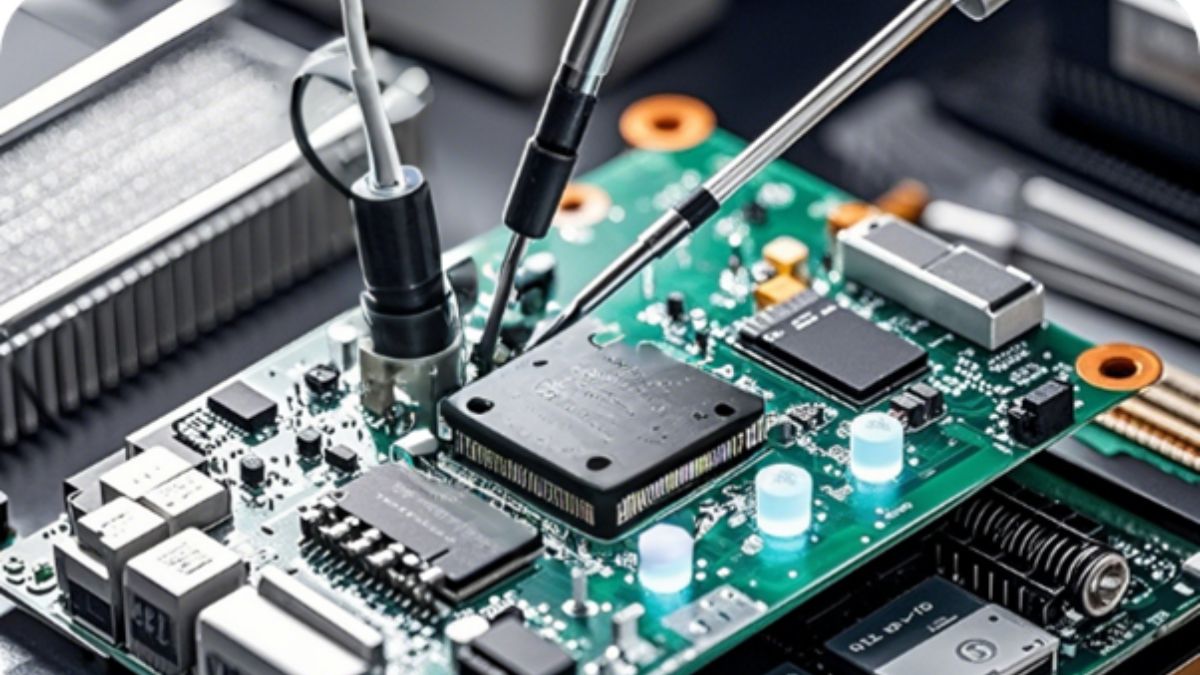

Precision equipment—such as CNC machines, micro-machining tools, laser cutting, and additive manufacturing, where applicable—ensures parts are made precisely as designed. Slight deviations can result in device failure, patient injury, or regulatory rejection. For example, a tiny error in a connector, sensor, or implant geometry may compromise fit or function.

Precision also supports consistency across batches, which is a regulatory must. Without reliable machines and equipment, variation creeps in, and the risk of nonconforming devices rises.

Process validation: IQ, OQ, PQ

Precision equipment must not only be capable of producing accurate parts, but this capability must be verified and documented via:

- Installation Qualification (IQ): confirming that equipment is installed correctly according to specifications.

- Operational Qualification (OQ): ensuring equipment operates under set conditions and delivers expected outputs.

Performance Qualification (PQ): showing that equipment performs consistently under real-world production conditions.

These stages are essential to satisfy regulators and auditors.

Special considerations when using polyurethane or casting parts

When using materials or methods like polyurethane casting, specialized precision equipment becomes crucial:

- Polyurethane parts might be used in devices or components that come into contact with the body, or in seals, housings, or flexible parts. In such cases, the processing must ensure no contamination, correct curing, correct geometry, and material consistency. Working with a reliable polyurethane processing equipment manufacturer ensures that these parts are produced to regulatory-acceptable standards.

- Similarly, when polyurethane casting machines are used to create parts, the machines must maintain tight control over temperature, mixing ratios, molds, curing times, etc. All these parameters affect material properties, dimensional stability, and safety (e.g., release of residual monomers). Regulators will expect complete documentation, traceability, and consistent validation of those machines and processes.

Best practices for manufacturers

1. Equipment calibration and maintenance

Regular calibration of measuring devices, inspection machinery, and production equipment is nonnegotiable. Scheduled maintenance prevents drift, reduces variation, and helps maintain the precision required by regulators.

2. Documentation and traceability

Every step—from raw material sourcing, machine settings, validation reports, and environmental conditions—to final inspection must be documented. Good documentation supports audits, helps investigate issues, and ensures compliance with standards like ISO 13485 or FDA QS.

3. Training and qualification

Skilled operators and engineers must understand both how to use precision equipment and why each parameter is crucial for safety and compliance with regulations. Training, qualification, and periodic retraining ensure that human error is minimized.

Navigating regulatory compliance in medical device manufacturing demands precision—in materials, in measurements, in processes, and in documentation. Without the right precision equipment—and without validating and maintaining it properly—manufacturers risk failures that could hurt patients, derail product approvals, or damage reputations. Whether one is working with a polyurethane processing equipment manufacturer to supply parts or deploying polyurethane casting machines in production, the commitment to accuracy, traceability, and compliance must be unwavering. Embracing best practices, staying current with evolving standards, and investing in equipment and personnel are key steps toward delivering safe, effective, and market-approved medical devices.