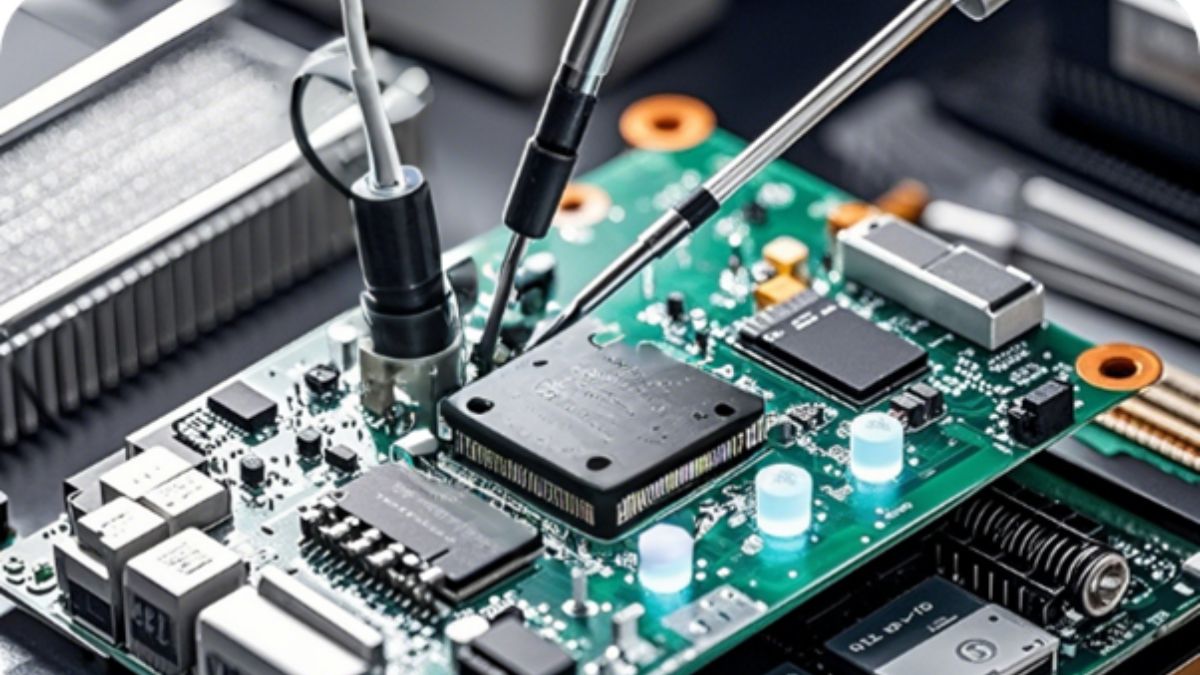

Understanding Precision CNC Machining

Precision CNC machining is a subtractive computer controlled procedure that uses guided tools to form workpieces. It is extremely precise and can achieve a tight tolerance of 0.0.01mm with ease.

The automotive industry uses multi axis CNC machines such as 3-axis and 5-axis machines to manufacture precision parts. It heavily relies on precision CNC machining for its high quality surface finish and efficiency.

The process initiatives from a CAD model and followed by CAM modeling to produce G-codes instructions that guide the machining tools determine feed rate and monitor the spindle speed.

The CNC process eliminates the factor of human error present in manual machining. This makes the process more reliable, consistent and repeatable for intricate features such as thread and undercuts.

This article focuses on the use of CNC machining in the automotive industry, how it has benefitted the industry and parts are typically precision-machined while also highlighting the parameters and abilities of CNC machining.

Key Automobile Parts Manufactured with CNC Machining

Engine Components

Engine parts require exceptionally high dimensional accuracy and precision, CNC machines adequately deliver components with high surface finish and precision.

The process of high speed milling is typically used to machine aluminum alloy cylinder heads that require precision to maintain the appropriate compression ratio in the combustion chamber and properly maintain the valve seal.

The CNC process of turning is used in manufacturing crankshafts. The process is useful in balancing the rotational dynamics of the components which help to minimize the vibrations at high RPMs.

Additionally the camshaft has a lobe profile that requires grinding to ensure precision so it syncs with valve timings whereas other components such as cylinders and pistons are milled and bored.

The process integrates coolant systems to improve thermal management for certain materials with high thermal conductivity

Transmission Parts

Transmission components such as gears are made using high strength alloys to compensate bearing cyclic loads. CNCn machining can process the alloy with precision and produce gears that are standardized to AGMA regulations.

Shafts have to undergo various CNC procedures such as turning and grinding. This is done to ensure alignment in gear assemblies.

Multi-axis CNC setups enable simultaneous machining of complex contours, reducing setup times and improving concentricity.

Brake System Components

Brake parts such as calipers are essential for a car to function properly as bad parts can cause safety concerns and hazards. They are milled from billet aluminum or cast iron with tight tolerance of 0.005 mm to ensure reliability and prevent any fluid leakage.

Rotors are turned to balance the weight distribution whereas pistons and brackets are chamfered and threaded to ensure proper assembly CNC machining ensures proper seals and precision.

Suspension and Steering Parts

Suspension and steering such as ball joints and control arms are typically machined from forged aluminum and reamed to ensure precision and high quality finish with minimal friction.

Steering knuckles feature integrated hubs that are milled and align perfectly with wheel bearings. Bushings and Mounts are bored with the help of finite element analysis to ensure stable handling.

Exhaust System Components

Exhaust manifolds feature contoured ports that reduce backpressure and optimize flow. The contours are made through 5-axis CNC machining to ensure optimal fluid dynamics.

Catalytic converter housings are made by turning and welding incorporating features for sensors and adaptors. CNC machining is also used to manufacture turbo charger interfaces made from inconel to withstand the temperature fluctuation.

Interior and Exterior Trim Parts

Most interior parts are made using various composites that are processed using CNC machining for a refined and slick look. Chamfered edge and high quality surface finishes with precise fitting are achieved through CNC machining.

Exterior details such as emblems are refined through micromilling and door handles are contoured using lathe machines while grills have various patterns to optimize air flow.

CNC processes allow manufacturers to rapidly iterate designs to incorporate textures via bead blasting or anodizing for enhanced durability.

Materials Used in CNC Machining for Automobile Parts

The automotive industry mainly works with high strength material that have excellent physical and chemical property such as tensile strength and corrosion resistance

Aluminum alloy such as 6061-T6 is used to make engine blocks due to its high strength to weight ratio and excellent thermal conductivity to help in heat dissipation.

Steels such as 4140 chromoly have superior hardness for transmission gears and are rated at rockwell C 30-40 after heat treatment.

Stainless steels such as (304/316) are used in exhaust systems whereas titanium is employed in high performance components that have to be light weight and require high fatigue resistance.

Polymers such as nylon 66 and ABS are low density light weight and durable, often a primary choice for interior trims and parts.

Material selection considers factors like Young’s modulus and coefficient of thermal expansion to ensure compatibility in assemblies.

Benefits of Precision CNC Machining for Automotive Components

Accuracy and Consistency

CNC machining offers the automotive industry high precision and tight tolerances. It can achieve a tolerance of 0.02mm which is crucial to ensure parts such as piston and cylinders maintain a tight seal.

Additionally CNC machines enable large scale production with consistency and reliability. CNC also allows automation in the production process which reduces labor cost and streamlines the process increasing efficiency.

Cost-Effectiveness

The CNC machining process integrates various softwares that virtually simulate the process and optimize the tool path to reduce scrap rates and minimize tool wear.

CNC manic can be fully automated to boost efficiency and production rate, modern multi axis CNC machines reduce the need for multiple setup and jigs.

Cycle time for complex parts are reduced by 50% compared to traditional methods, all the procedures make the process more cost effective while producing higher quality parts and components

Efficiency and Speed

CNC machines use high speed spindles (up to 20,000 RPM) that have predetermined quick precise movements to minimize time and boost efficiency.

The integration of robotics and adaptive control systems adjust parameters in real time to maintain efficiency in real time with variable conditions.

Enhanced Durability and Performance

Precision machined components have improved stress distribution which extends a component fatigue life.

Precision machines also help to optimize geometries such as in turbine blades and turbo chargers to boost efficiency. Additionally this improve fuel economy and reduces wear

Sustainable Manufacturing Practices

CNC machining minimizes waste and optimizes energy consumption through path optimization. It has a recovery rate of 95% for metals such aluminum which helps to reduce raw resource demand.

Modern CNC machines use energy efficient spindles and variable frequency drives which cut power consumption. Dry machining is also an option for materials that are prone to heat, it helps to eliminate coolant waste

Using biodegradable lubricants and closed-loop systems further aligns with environmental standards, supporting circular economy principles in part remanufacturing.

Conclusion

Precision CNC machining has been adopted by the automotive industry due to its reliability and precision in manufacturing components with tight tolerance.Reducing cost while raising quality standards and efficiency has been the primary reason for its widespread adoption.

Its components production for the automotive industry ranges from engine cylinders to interior trims and exterior insignias.

Through the use of advanced control systems and automation it has revolutionized the production industry by driving engineering advancements.

As automotive demands evolve toward electrification and autonomy, CNC technologies will continue to drive innovation in component design and performance.