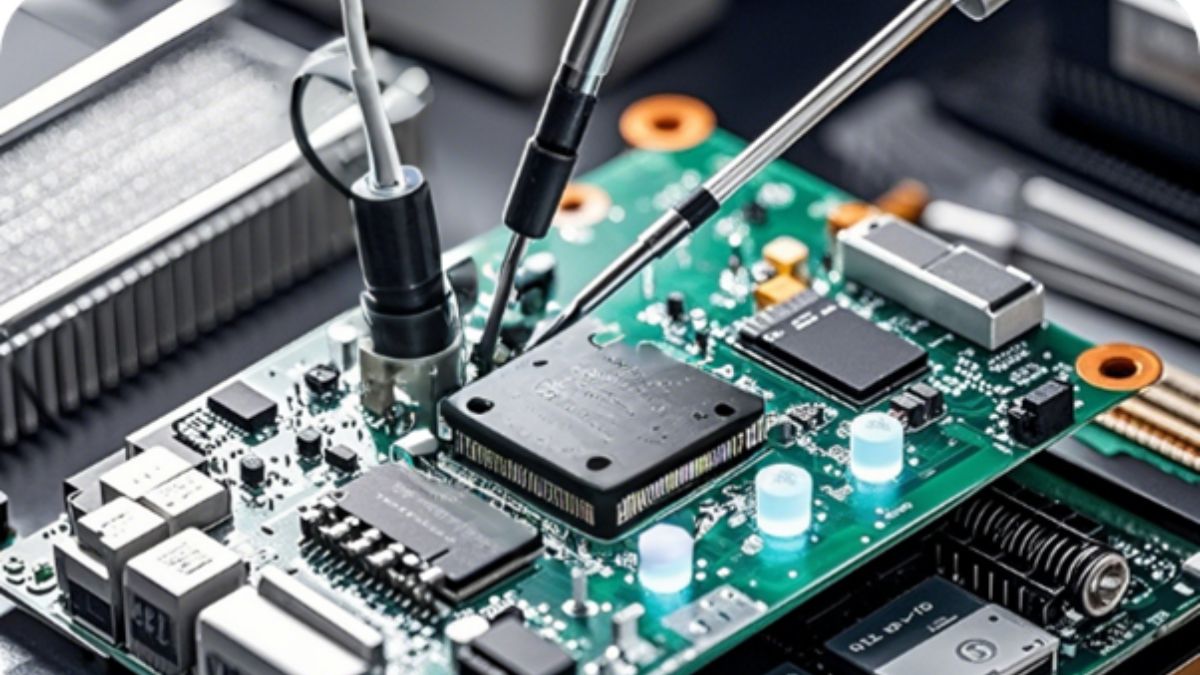

As electronic devices become increasingly compact and feature-rich, engineers face the challenge of fitting more functionality into smaller spaces without compromising reliability. Traditional rigid PCBs often limit design possibilities when space constraints and mechanical flexibility are required. This is where rigid flex pcb design and FastTurn PCB services offer an advanced and practical solution for modern electronics.

Rigid flex PCB design combines rigid and flexible circuit technologies into a single board structure, allowing the PCB to bend, fold, and fit into complex shapes. When this innovative design approach is supported by FastTurn PCB manufacturing, companies can prototype and produce these advanced boards quickly, accelerating product development and reducing time to market.

Understanding Rigid Flex PCB Design

Rigid flex PCB design involves creating a circuit board that integrates rigid sections for component mounting with flexible layers that allow movement and bending. These flexible sections are typically made from polyimide materials, while the rigid parts are constructed from FR-4 substrates.

The main goal of rigid flex PCB design is to eliminate the need for connectors, cables, and separate boards. By combining everything into one unit, designers can create more compact, lightweight, and reliable electronic assemblies.

This design approach is especially useful in products that require three-dimensional layouts or must fit into tight enclosures.

Key Principles of Rigid Flex PCB Design

Design for Flexibility

The flexible areas must be carefully designed to withstand repeated bending without damaging the circuit. Proper bend radius and material selection are critical.

Layer Stack Planning

Rigid flex boards often include multiple layers. Proper stack-up planning ensures electrical performance and mechanical strength.

Minimizing Stress Points

Designers must avoid placing vias, pads, or components in areas that will experience frequent bending.

Signal Integrity Considerations

Controlled impedance, grounding, and shielding are important for maintaining signal quality, especially in high-speed circuits.

Space Optimization

The design allows the PCB to fold into compact shapes, making efficient use of available space inside the device.

Advantages of Rigid Flex PCB Design

Rigid flex PCB design offers several benefits that traditional PCBs cannot match.

- Reduced need for connectors and wiring

- Increased reliability due to fewer interconnections

- Lightweight and compact assembly

- Improved electrical performance

- Greater design freedom for complex layouts

These advantages make rigid flex PCBs ideal for advanced applications in multiple industries.

Applications of Rigid Flex PCB Design

Rigid flex PCB design is widely used in industries where compact size and durability are essential.

- Medical devices such as wearable monitors and implants

- Aerospace and defense systems exposed to vibration and extreme temperatures

- Consumer electronics including smartphones, cameras, and tablets

- Automotive electronics and control modules

- Industrial automation equipment

In these applications, the ability to combine flexibility and strength in one board is highly valuable.

What is FastTurn PCB?

While advanced PCB design is important, speed in manufacturing is equally critical. FastTurn PCB refers to rapid PCB prototyping and production services that deliver boards within a short time frame, often in just a few days.

FastTurn PCB services allow engineers to quickly test their rigid flex PCB designs, identify issues, and make improvements without long waiting periods.

Benefits of FastTurn PCB Services

Rapid Prototyping

Designers can receive prototypes quickly, enabling immediate testing and validation.

Faster Development Cycles

Short turnaround times help reduce project delays and speed up product development.

Quick Design Iterations

When changes are required, FastTurn PCB services allow revised boards to be produced rapidly.

Competitive Time to Market

Companies can launch products faster by minimizing PCB production delays.

The Advantage of Combining Rigid Flex PCB Design with FastTurn PCB

The true advantage comes from combining thoughtful rigid flex PCB design with FastTurn PCB manufacturing. Complex boards that would traditionally take weeks to produce can now be delivered in days for testing and refinement.

For example, a wearable device designer can create a rigid flex PCB that fits perfectly into a compact enclosure and receive a prototype quickly. This allows early testing of fit, functionality, and durability, reducing development risks before mass production.

This combination is particularly beneficial in industries where innovation and speed are both essential.

Choosing the Right PCB Manufacturer

When selecting a manufacturer for rigid flex PCB design and FastTurn PCB services, consider the following:

- Experience with rigid flex PCB design and manufacturing

- Advanced equipment for precise production

- Ability to provide FastTurn PCB without compromising quality

- Strong testing and quality assurance processes

- Technical support for design optimization

A reliable manufacturer ensures that both design complexity and fast delivery requirements are handled effectively.

Conclusion

The growing demand for smaller, smarter, and more reliable electronic devices has made rigid flex PCB design a crucial part of modern engineering. These boards offer unmatched flexibility, compactness, and durability for complex applications.

At the same time, FastTurn PCB services provide the speed required to prototype, test, and launch products quickly. Together, they enable businesses to innovate efficiently, reduce development time, and stay competitive in today’s fast-moving technology landscape.

Whether for medical devices, aerospace systems, automotive electronics, or consumer gadgets, rigid flex PCB design supported by FastTurn PCB manufacturing represents the future of advanced electronics development.